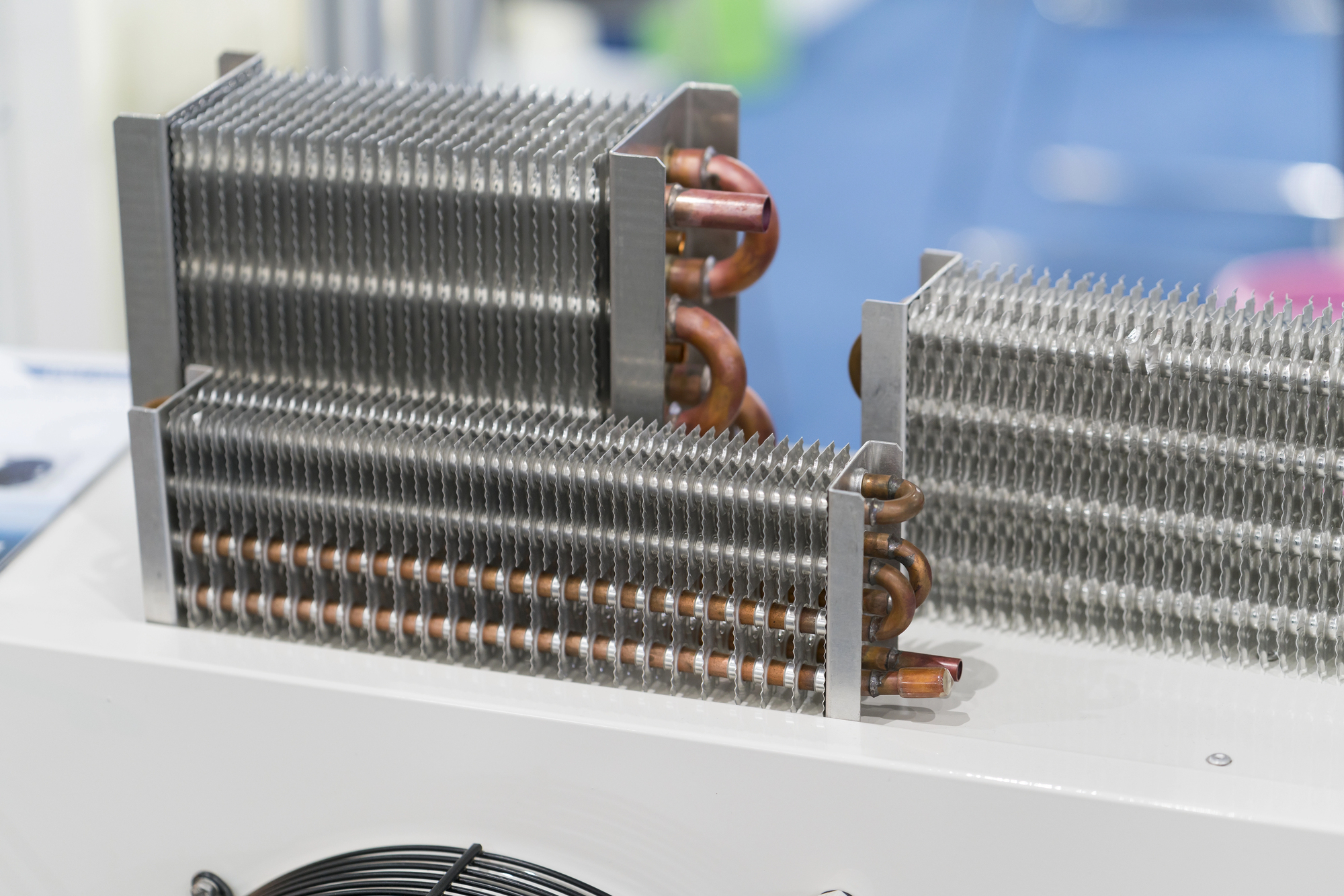

Superior Heat Transfer: Why Copper Shines

Copper stands out for its high thermal conductivity—about 60% better than aluminum—making it a top choice for high-efficiency heat transfer in demanding applications like industrial systems, radiators, and electronics cooling. Its rapid heat conduction ensures efficient energy use and consistent performance.